venturi flow meter formula

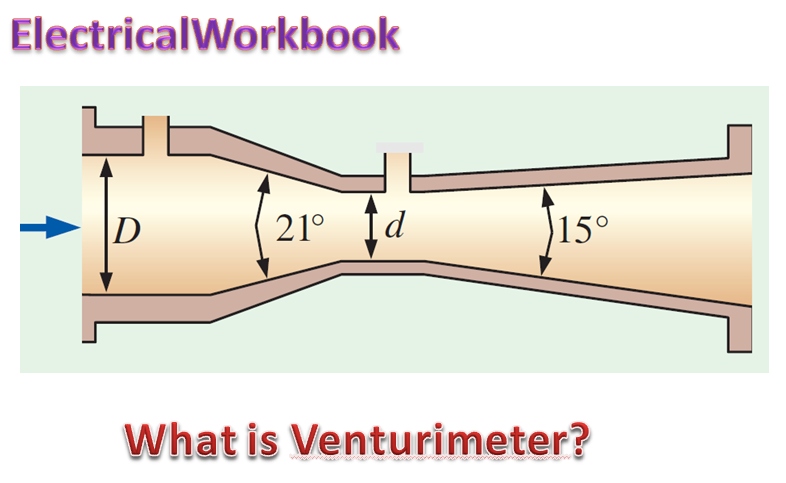

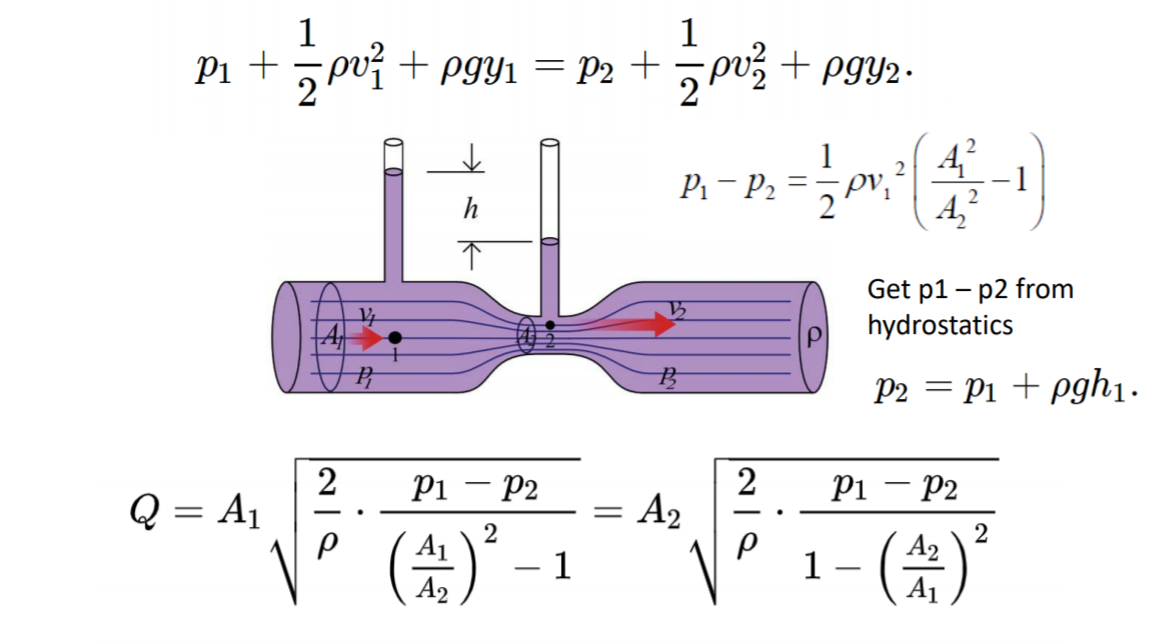

The equation is based on the Bernoulli equation conservation of energy and the continuity equation. This enables the venture to be fitted to the pipe.

Components Of Reciprocating Pump Components Pumps Sump

Generally the following guidelines should be followed when installing venturi meters.

. The restriction diameter should not be less than 0224 D and not more than 0742 D where D is the nominal bore diameter of the pipe. Construction of Venturi meter. By employing the continuity equation and Bernoullis principle the volumetric flow rate through the orifice meter can be calculated as described previously for venturi meter.

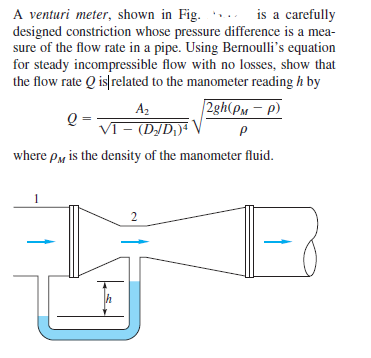

For casted tube are. The formula above can be used with limitations for applications with relatively small changes in pressure and density. After the entry there is a converging conical section with an included angle of 19 to 23.

Most flow meters have to be installed a specified distance before and after piping components that will affect the fluid in the line. Engineers can measure the change in pressure using Venturi meters and nozzles which tell you the flow rate. ISO 51672003 Venturi Calculation.

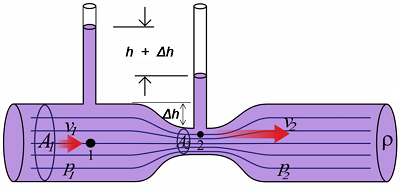

Venturimeter entrance is a straight cylindrical section with a length equal to 5 to 8 times the pipe diameter. The Venturi effect is the reduction in fluid pressure. It has a tube of broad diameter and a small constriction towards the middle.

The equation is based on the Bernoulli equation conservation of energy and the continuity equation. Venturi tubes are available in sizes up to 72 and can pass 25 to 50 more flow than an orifice with the same pressure drop. BIF has been building and testing venturi flow meters for years to develop the ideal combination of accurate flow measurement and low head loss.

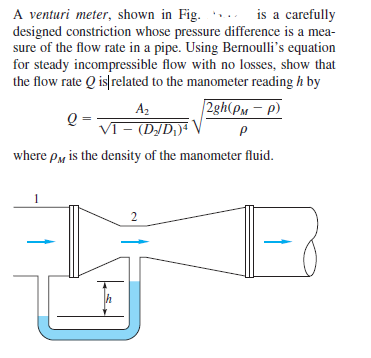

Venturi Meter Click Here for Sample Questions A venturi meter is a device that is used to measure the speed flow of incompressible fluid. The conical angle is normally 21 0 2 0While the liquid flows inside the venturimeter the velocity of fluid increases at the expense of a decrease in. Venturi flow meters like all other types of differential pressure flow meters function on the principles of the Bernoulli equation which states that as the speed of the flow of a fluid increases pressure loss occurs.

Venturi Meter is a device in which pressure energy is converted into kinetic energy and it is used for measuring the rate of flow of liquid through pipes. The device converts pressure energy into kinetic energy and measures the rate of flow of liquid through pipes. A flow of air through a Pitot tube Venturi meter showing the columns connected in a manometer and partially filled with water.

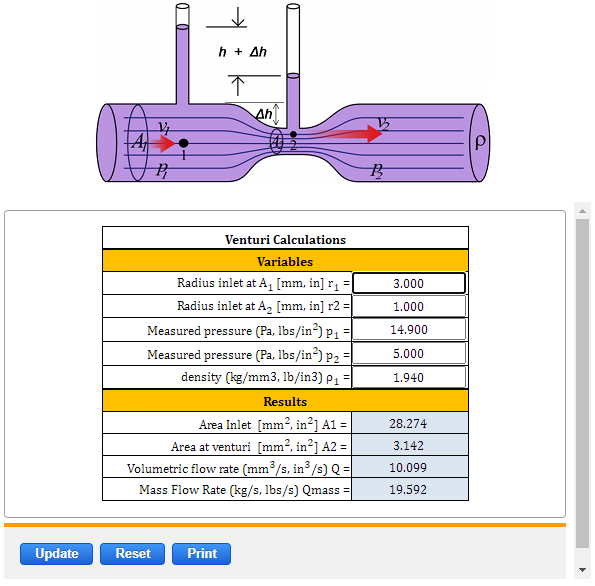

Where C v is the Venturi coefficient A 1 and A 2 are the areas of the pipe cross-section ΔP is the difference between the pressure in A 1 and A 2 and ρair us the density of air. FLOCALC calculation reference F076. Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full.

In this section the venturi meter tube diameter gradually decreases. The following are the main parts and areas of venture meter. The venturi meter is a flow meter that used where high-pressure recovery is required.

Example - Kerosene Flow Through a Venturi Meter. Installing a proper venturi meter is the solution to correct operation. Aug 16 2016 3427.

Figure 2 shows an orifice meter with the variable position of vena contracta with respect to the orifice plate. Idealized flow in a Venturi tube. The meter can measure the fluid flow and reduce its flow when necessary.

To find the Coefficient of discharge then we have to divide actual discharge by the theoretical discharge. According to the formula the flow rate can be calculated according to the following formula. A venturi tube contains a throat which is smaller in a diameter to the pipeline into which it fits.

ISO 5167-11991 Venturi Calculation. The pressure difference dp p 1 - p 2 between upstream and downstream is 100 kPa 1 10 5 Nm 2. Solving for pressure differential.

The Venturi flometer is used in a variety of industrial applications that include gas liquids slurries and other processes where permanent pressure loss is not acceptable. Video of a Venturi meter used in a lab experiment. In modern applications the principal advantage.

Used in the Medical industry. The direction of flow in the venturi meter should be checked and set up to agree the flow direction. Posted in Fluid Dynamics.

A Venturi flowmeter requires two pressure and one temperature measurement to accurately determine flow. Therefore venturimeters should be installed following the manufacturers guidelines. The CV Venturi Flow Meter is a differential pressure element de signed to accurately measure the flow of liquids and gases by forcing the flow into a smaller diameter section of pipe then measuring the pressure differences between the unrestricted flow and the restricted flow.

Venturi meter flow rate measures the velocity of. The entry of the venture is cylindrical in shape to match the size of the pipe through which fluid flows. Where a b and c depend on the type of Venturi tube.

Piping Conditions That Can Affect Venturi Flow Meter Performance. In this calculator for coefficient off discharge C following equation has been used. For welded tube these coefficients are.

It is invented by American Engineer Clemans Herchel and named by the Italian physicist Giovanni Venturi. Flow Measurement Engineering Handbook 2 nd Edition RW Miller. It works on the basic principle of Bernoullis Equation.

The meter is read as a differential pressure head in cm or inches of water. FLOCALC calculation reference K075. Written by Jerry Ratzlaff on 21 January 2016.

Hence 3 8 6 5 6 ¼ À Ì. Fluid flow is calculated when the meter checks the pressure difference between the two readings and the temperature. It can be installed in any position with.

Venturi Meter Flow Rate. Based on the conditions of the experiment C v equals 08159. The venturi meter device measures the flow rate or velocity of a fluid through a pipe.

When the fluid flows through it the pressure at the throat is lower than the upstream. The venturi meter device measures the flow rate or velocity of a fluid through a pipe. Solving For Flow Rate.

Answered A Venturi Meter Shown In Fig Designed Bartleby

Flowrate Calculation For A Venturi

Venturi Meter Engineeringclicks

What Is Venturimeter Working Construction Applications Electricalworkbook

Flowrate Calculation For A Venturi

Venturi Meter Design Equations Formulas Calculator Flow Rate

Difference Between Absolute And Gauge Pressure Vacuum Abs Pressure Gauges

Chapter 11 Example 11 The Venturi Meter Youtube

Venturi Meter Problems Bernolli S Principle Equation Of Continuity Fluid Dynamics Youtube

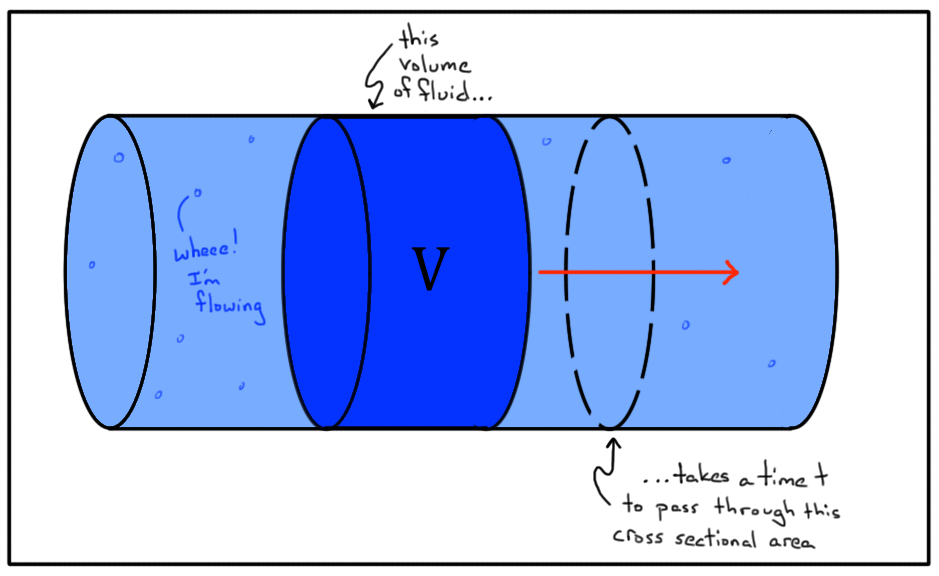

What Is Volume Flow Rate Article Fluids Khan Academy

Venturi Flowmeter Flowmaxx Engineering

Bernoulli S Equation Venturi Meter

Venturi Flow Equation And Calculator

Venturi Flow Equation And Calculator

Solved A Formula Is Given For The Volumetric Flow Rate Chegg Com

The Principle Of The Transit Time Ultrasonic Flow Measurement Method Download Scientific Diagram

Flow Transmitters Questions And Answers Question And Answer Interview Questions And Answers Answers